- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Size: 54CBM

- Place of Origin: Shandong

- Brand Name: beer equipment

- Model Number: CN-DEGONG

- Weight: 10000.000 kg

Degong Equipment Technology Co.,Ltd Jinan. www.idegong.com

you can check our further equipment information and then give me your inqiury.

Following are my introduction of beer equipment:

Part 1, Milling Unit

1. Flexible or steel auger for option

Part 2, Micro Brewhouse

1.Mash tun, Lauter tun, Boiling Kettle, Whirlpool tun in various combination

2. Hot water tank and cold water tank for optional in special combinations

3. Infusion or decoction brewing methods are designed exactly

4. Stainless steel or copper cladding are popular

5. Two stages or single stage heat exchanger for wort cooling

6. Completely stainless steel integrated work platform

7. Sanitary and efficiency wort pump

8. All pipes and fittings

Part 3, Fermentation Tank

1. Standard stainless steel conical cylindrical fermentation tanks

2. Single size as brewhouse is common used in restaurant

3. Tanks quantity is exactly calculated by fermentation cycle for various beers

4. All manhole, valves, pressure gauges, fittings etc are included

Part 5, Beer Bright Tank

1. Standard stainless steel bright tanks for beer maturation, conditioning,

2. Single size as fermenter is common used in restaurant or bar

3. Tanks quantity is exactly calculated for various beers and the function

4. All manhole, valves, stone, gauges, fittings etc are included

Part 6, Glycol Water Cooling Unit

1. Insulated glycol water tank with or without copper coil for glycol liquid holding and mixing

2. Efficiency chillers or refrigerators with fryonto supply cooling energy

3. Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger

4. All pipes, fitting, insulation materials are included

Part 7, Controlling Unit

1. Electrical controlling cabinet with temperature, on-off controlling for brewhouse

2. Electrical controlling cabinet with temperature, on-off controlling for cooling parts

3. Temperature controller, thermocouple, solenoid valves etc are included

4. PLC with touch screen panel for special request

Part 8, Other Facilities

1. Portable CIP system for cleaning the tanks

2. Steam boiler for brewhouse heating

3. Water treatment for brew water

4. Oil free air compressor

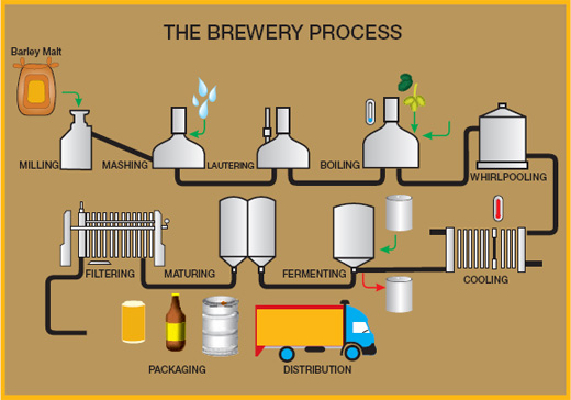

Brewing process for mini beer brewery:

1) Crushing and saccharification

Grind the malt to powder, make the wort after mashing transported to the filter pan by a pipeline

2) Filter:

Send the wort after mashing boiled to wine tank filtration, separate the wort and spent grains

3) Boil and add hops

Transferred to cooking wine cooking water tank with 100 degrees about 70 minutes, After adding hops, cooking the wort to the remaining 1000L till then along the pipeline transported to the fermentation room Cooling

4) Cooling

The wort’s temperature is lowered to 10-12 C by cooler, then go into the fermentation tanks to ferment.

5) Fermentation:

After adequate cooled wort into the fermenter, adding 10 - 15L of yeast for fermentation, takes about six days left to complete the fermentation, in this step will be the final malt in the sugar into alcohol by yeast (yeast Jiamai juice = Beer )

6) Slaking and storage:

Mature in the beer store as the necessary steps before ripening, beer maturation takes about three weeks of storage at 0 ° C for cask beer color, unique flavor development in this step will be the formation

Looking forward to your further reply on our equipment or about equipment brewing.

- Size: 54CBM

- Place of Origin: Shandong

- Brand Name: beer equipment

- Model Number: CN-DEGONG

- Weight: 10000.000 kg

Degong Equipment Technology Co.,Ltd Jinan. www.idegong.com

you can check our further equipment information and then give me your inqiury.

Following are my introduction of beer equipment:

Part 1, Milling Unit

1. Flexible or steel auger for option

Part 2, Micro Brewhouse

1.Mash tun, Lauter tun, Boiling Kettle, Whirlpool tun in various combination

2. Hot water tank and cold water tank for optional in special combinations

3. Infusion or decoction brewing methods are designed exactly

4. Stainless steel or copper cladding are popular

5. Two stages or single stage heat exchanger for wort cooling

6. Completely stainless steel integrated work platform

7. Sanitary and efficiency wort pump

8. All pipes and fittings

Part 3, Fermentation Tank

1. Standard stainless steel conical cylindrical fermentation tanks

2. Single size as brewhouse is common used in restaurant

3. Tanks quantity is exactly calculated by fermentation cycle for various beers

4. All manhole, valves, pressure gauges, fittings etc are included

Part 5, Beer Bright Tank

1. Standard stainless steel bright tanks for beer maturation, conditioning,

2. Single size as fermenter is common used in restaurant or bar

3. Tanks quantity is exactly calculated for various beers and the function

4. All manhole, valves, stone, gauges, fittings etc are included

Part 6, Glycol Water Cooling Unit

1. Insulated glycol water tank with or without copper coil for glycol liquid holding and mixing

2. Efficiency chillers or refrigerators with fryonto supply cooling energy

3. Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger

4. All pipes, fitting, insulation materials are included

Part 7, Controlling Unit

1. Electrical controlling cabinet with temperature, on-off controlling for brewhouse

2. Electrical controlling cabinet with temperature, on-off controlling for cooling parts

3. Temperature controller, thermocouple, solenoid valves etc are included

4. PLC with touch screen panel for special request

Part 8, Other Facilities

1. Portable CIP system for cleaning the tanks

2. Steam boiler for brewhouse heating

3. Water treatment for brew water

4. Oil free air compressor

Brewing process for mini beer brewery:

1) Crushing and saccharification

Grind the malt to powder, make the wort after mashing transported to the filter pan by a pipeline

2) Filter:

Send the wort after mashing boiled to wine tank filtration, separate the wort and spent grains

3) Boil and add hops

Transferred to cooking wine cooking water tank with 100 degrees about 70 minutes, After adding hops, cooking the wort to the remaining 1000L till then along the pipeline transported to the fermentation room Cooling

4) Cooling

The wort’s temperature is lowered to 10-12 C by cooler, then go into the fermentation tanks to ferment.

5) Fermentation:

After adequate cooled wort into the fermenter, adding 10 - 15L of yeast for fermentation, takes about six days left to complete the fermentation, in this step will be the final malt in the sugar into alcohol by yeast (yeast Jiamai juice = Beer )

6) Slaking and storage:

Mature in the beer store as the necessary steps before ripening, beer maturation takes about three weeks of storage at 0 ° C for cask beer color, unique flavor development in this step will be the formation

Looking forward to your further reply on our equipment or about equipment brewing.